Vertical packaging machine for powder industry

VHVP offers the best solutions for your powder business

As a producer in the food industry, you know better than anyone that the standards in this sector are extremely high: efficiency and maximum uptime are vital. In addition, the total cost of ownership is an increasingly decisive factor when purchasing a new packaging machine. VH Vertical Packing specialises in the development, manufacture, installation and maintenance of sustainable packaging machines for packaging all forms of powders and granules.

The production and packaging of powder products is subject to very strict regulations regarding quality and hygiene. VHVP has developed the Centurion Powder specifically for this sector of the market. A machine that meets your requirements perfectly, because we know the specifications of vertical packaging in your industry inside out. You can always count on our expert advice and, where required, we offer customisation based on your specific needs and specifications.

Value for money with VH Powder

VH Powder is a user-friendly machine, easy to operate and with short set-up times. With high uptime, integrated dust extraction, static discharge and modest operating and maintenance costs, it represents a valuable investment.

Extremely high standards must be met when processing powder products

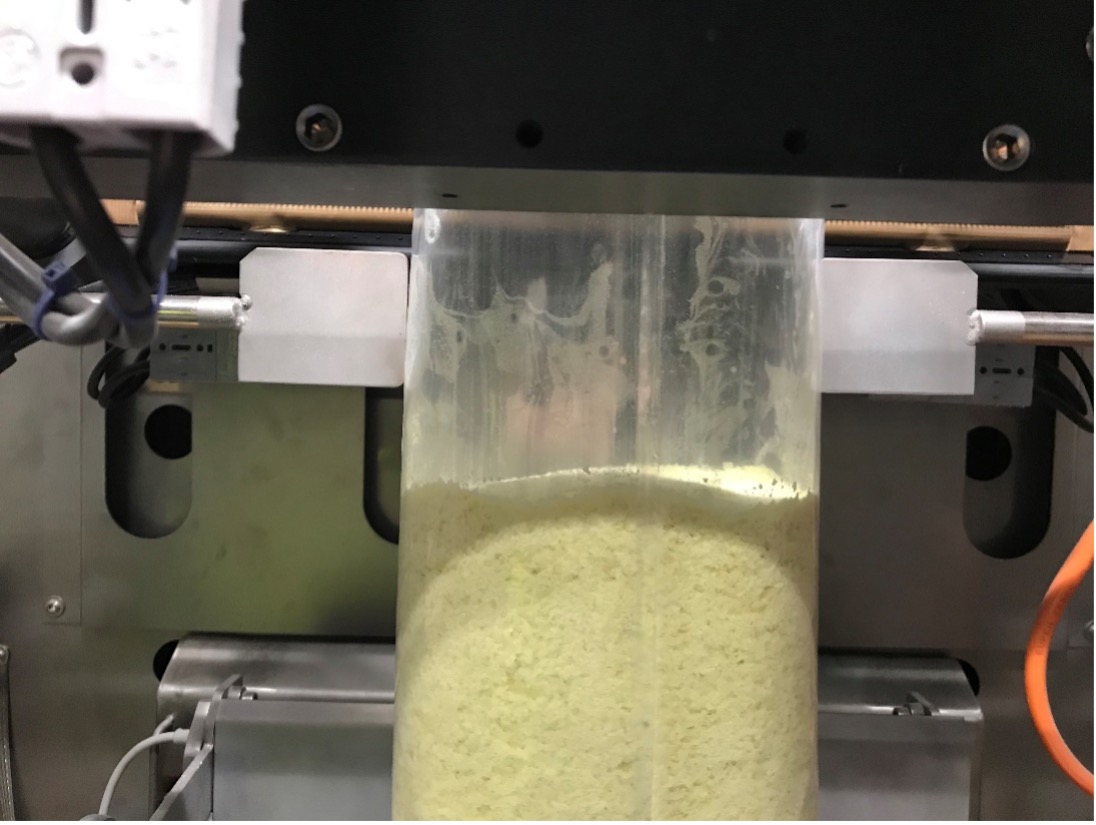

By using a screw doser, the product is dosed into the required packaging. This is often a compact set-up, and can be configured to be multifunctional. VH analyses the needs of line equipment according to the product and environment.

Your vertical packaging machine

User-friendly and accessible

Depending on the packaging, product, environment and budget, we help you make the right choice between the Centurion, Velteko or reconditioned Aquarius. We also provide guidance on the appropriate dosage system.

Our machines are equipped with our online Remote Engineer system, reducing the numbers of visits from our technicians. The operating system is highly advanced and easy to use. There is one central servo drive that is able to control three axes.

Familiar with the ins and outs of your industry

Powder processing has many bottlenecks and makes high demands on your machine

There must be the option to use the machine efficiently for packaging different types of powders and powder mixtures. Processors all face the following bottlenecks.

- A dusty environment causes:

– Contamination of film and associated sealing problems

– A lot of dust/contamination in the packaging line which is not easy to clean because of the product - Every powder is different. This creates a lot of variation in products and the necessary tooling is often not available.

- There should not be too much air in the pack, air expulsion is required

- Speed in small packaging is high, and the packers must also be able to handle large packaging. A large model of machine is required.

- Accumulated dust due to pouring the product into the packaging

- Static load

- Choice between volumetric or graphimetric filling, depending on homogeneity of the product

With VH Powder you are responding to changing market demands

Being able to respond quickly to the specific demands of users is important. When the market demand is constantly changing, the ability to be flexible and able to adapt quickly is highly desirable. With VH Powder, you are always well prepared for this: a smooth changeover between different types of packaging, resealable or not, etc. ensures a great deal of flexibility and continuity.

Your VH Powder machine

- The right packaging

- Easy to operate

- Short set-up times

- Three types of sealing systems: Heatseal - ROPEX/PTC and Omniseal

- Production performance in a simple MyCenturion System

- Integration of all necessary bag treatments

- Format including dust extraction

- Static discharge

- The right choice for dosing systems

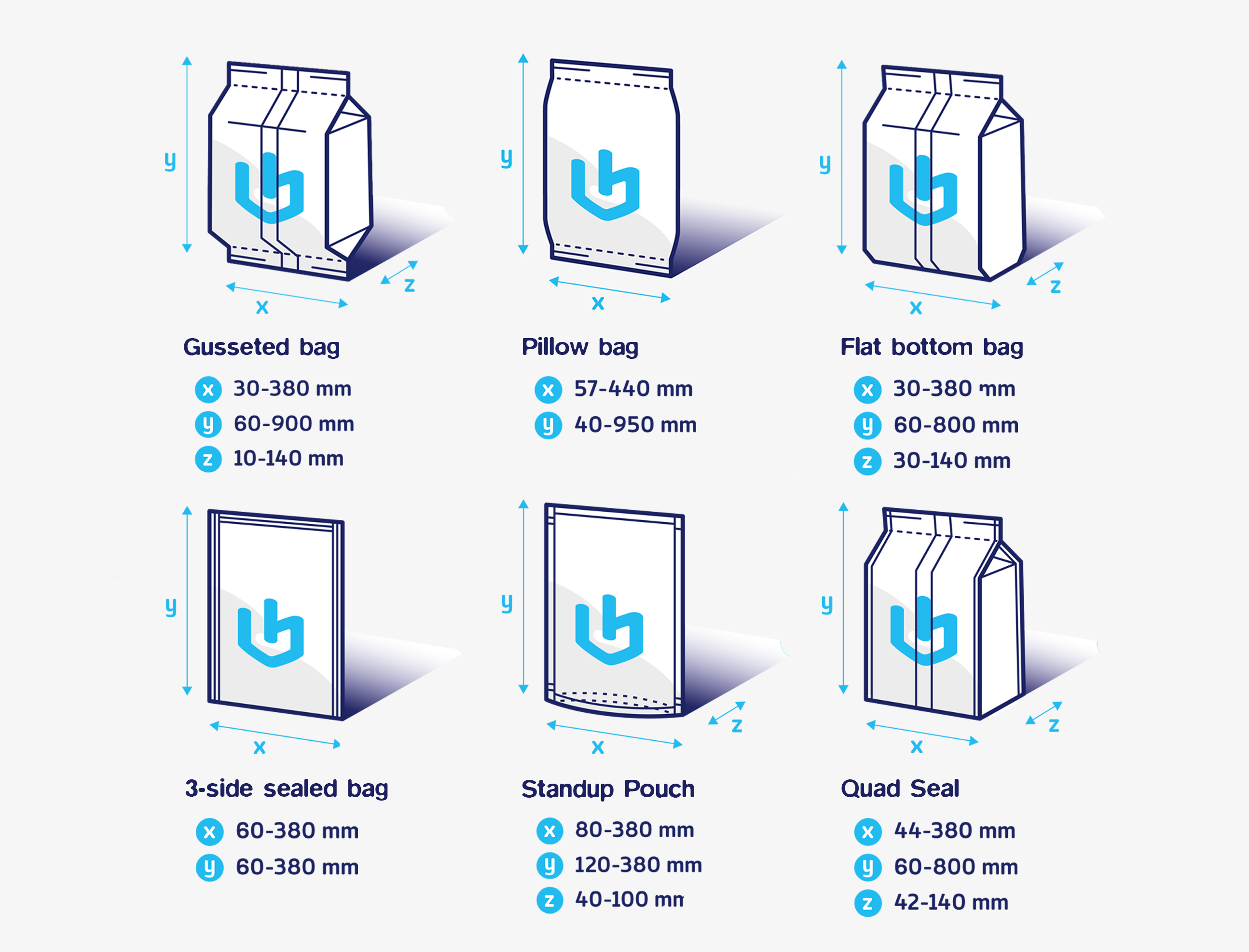

Different types of resealable packaging

Overview of practical applications

Basic applications needed in the Powder environment

- Format with dust extraction

- Screw doser supplied with:

- Volumetric filling for products with equal density

- Loss & Weight filling for products with variable density

- Integration with checkweigher / communication with dosing unit

- Horizontal feed screw to hopper: perfect filling to weights

- Compact design

- Easy tooling changeover

- Lifting aid tooling for bulk packaging

- Bag support for bulk packaging

- Static discharge around seal jaws and film path

- Microperforation behind the longitudinal seam for venting possible

- Perforation & easy opening on the cross jaw

Sealing systems

VH has three types of sealing systems:

- Heatseal:for laminated films and paper films.

- ROPEX/PTC:for polyethylene/monolayer film.

- Omniseal:for the combination of both.

Powder packers

Depending on bag type, length and weight, the following options are available for VH Powder:

- Bigbag losstation: to be able to pack a large volume of your product into small packaging, an unloading station automatically feeds it to a dosing unit.

- Feed screw: for the correct transport of the product to the dosing unit.

- Feed vacuum station:for the correct transport of the product to the dosing unit.

- Complete outfeed system: depending on product size and bag type, the appropriate support for the outfeed of the created package.

Hygiene

Depending on the layout and the feed scenario, we look at the most hygienic solution and at shielding the packer. VH Vertical Packing considers and advises per individual case, to ensure an optimal result.

LED - VH

For optimal operation of the line. There are often several lines that are served by one operator. Visual display of signals, such as pre-notification for end of film roll, are extremely practical and optimise efficiency.

Champion Feed convinced of VH Powder

We spent months doing our research into different brands, and this is how we came upon VH Vertical Packing. Freek Jacobs took lots of time with us, explained various aspects in great detail, and advised us on the machine that was ideally suited for packaging our powders. Mathieu did not hesitate to share his experience and confirm Freek’s advice. We were also introduced to Richard and Ruud, very professional guys. The pleasurable contact that we had, together with the trust created by the professional installation of our machine, were the deciding factors in choosing VH.

Nicolas Manders

Champion Feed

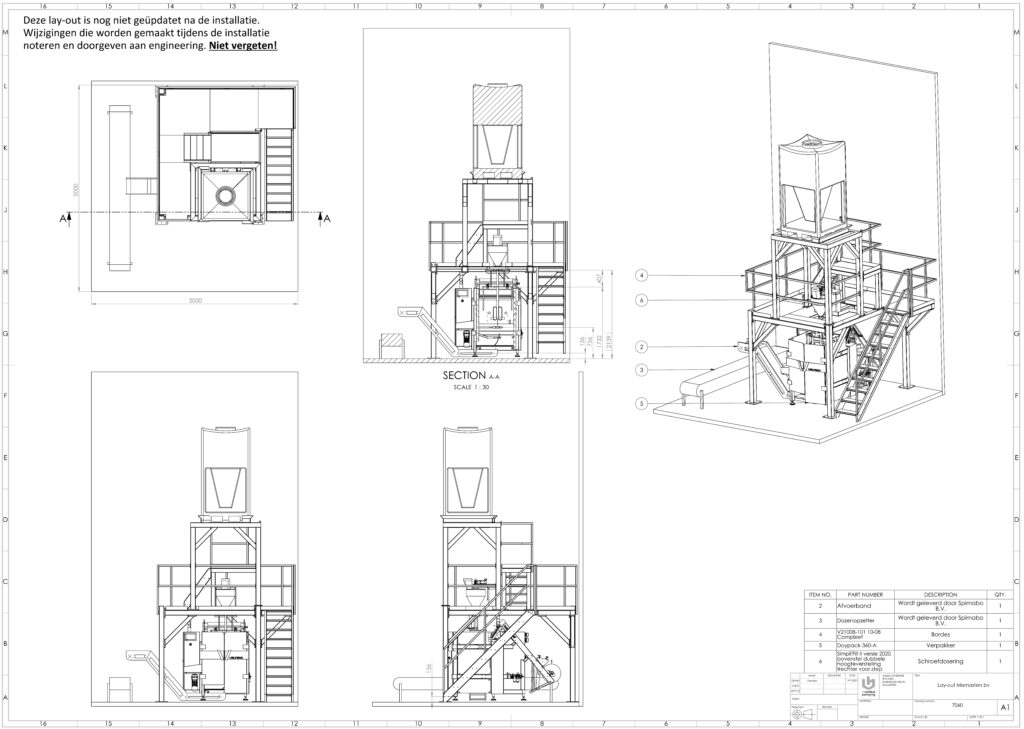

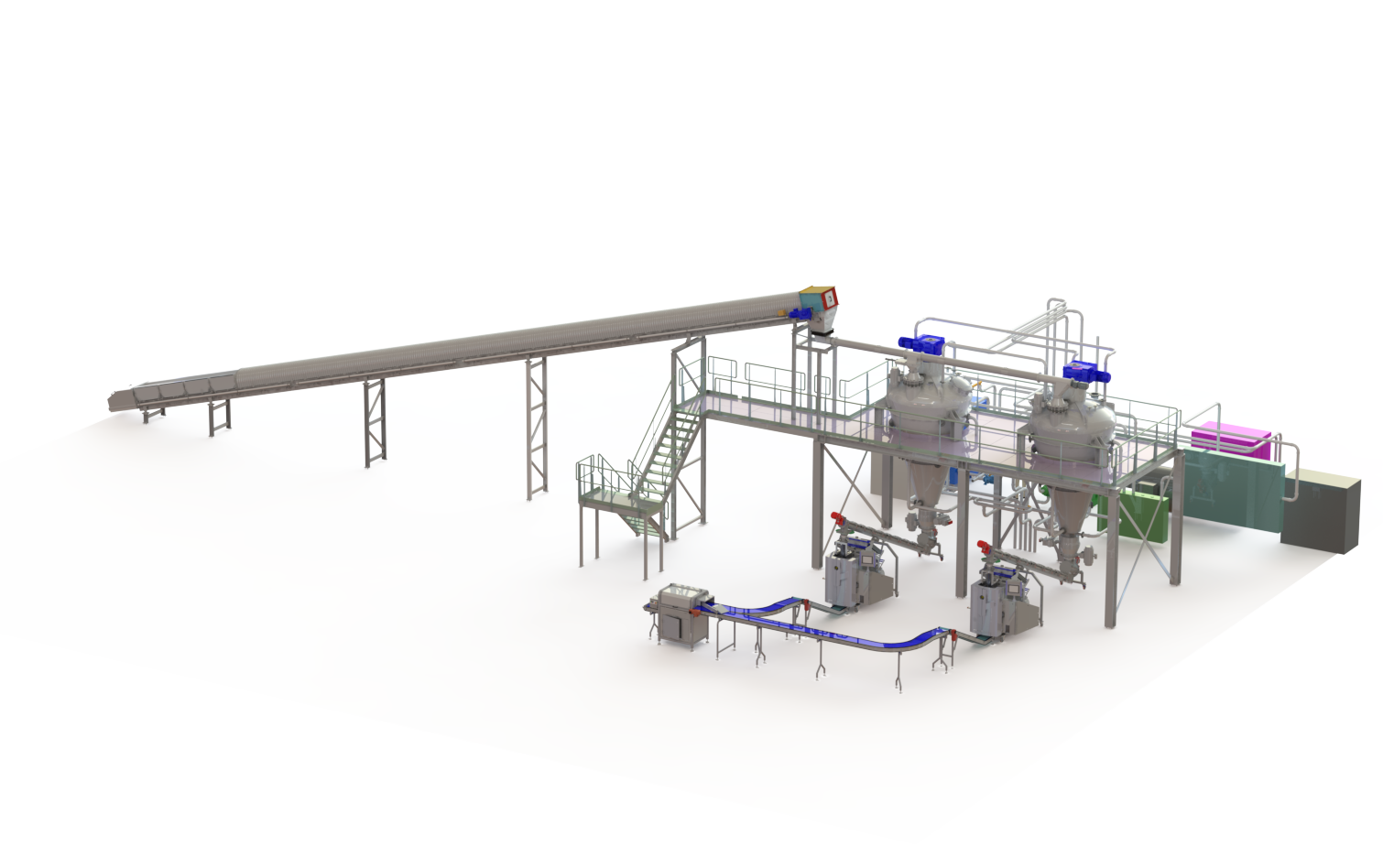

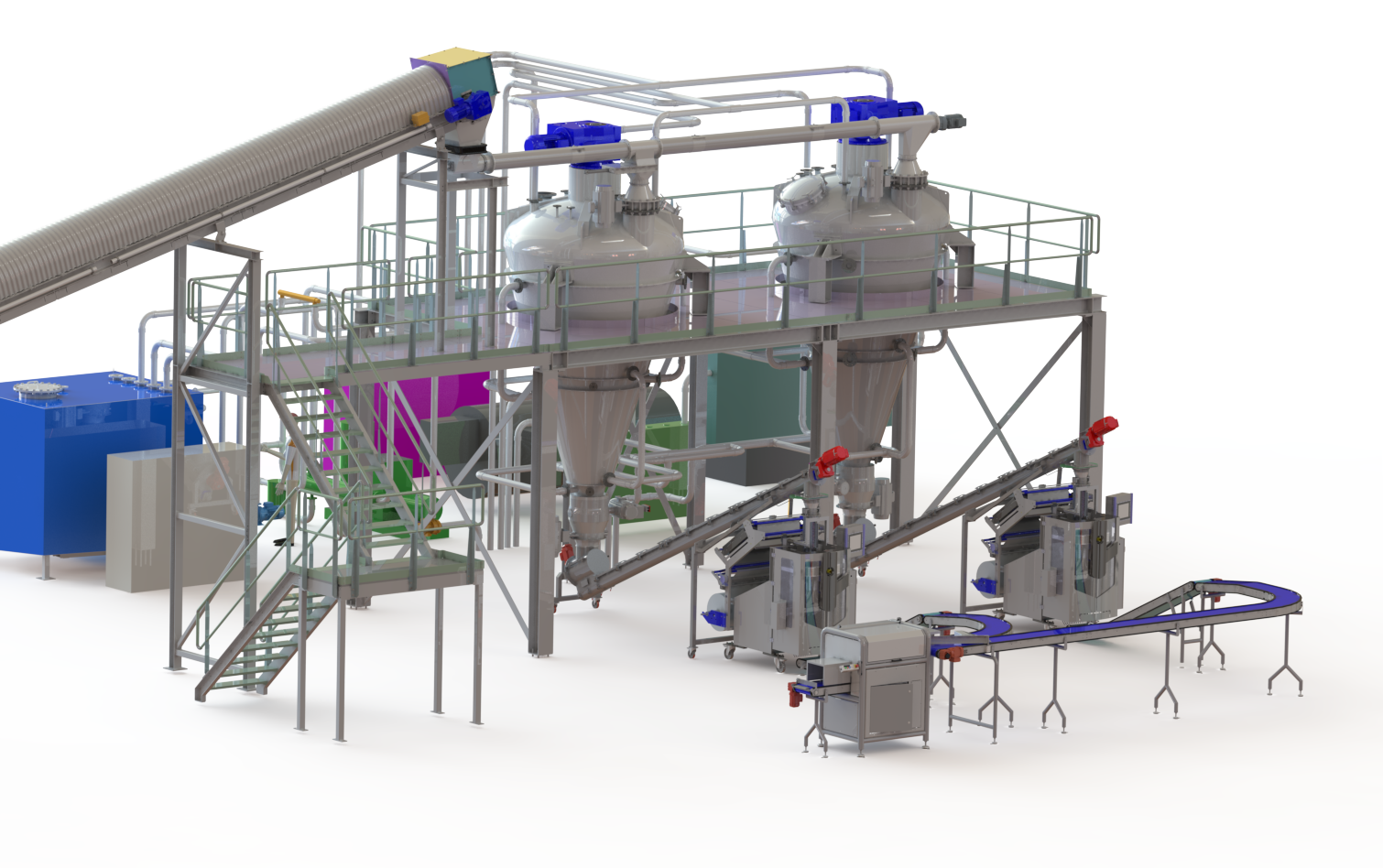

Turnkey oplossing for powder industry

Complete packaging lines with high efficiency

VH Vertical Packaging increasingly supplies turnkey solutions. Based on your requirements, a complete, customised packaging line is developed with the greatest care, with guaranteed high capacity and operational reliability. VH takes complete control, starting either from the infeed system, or after the elevating belt. This varies per client. From engineering to installation and commissioning, you will benefit from one dedicated point of contact. This is carried out in phases:

- Engineering in both 3D and 2D.

- Delivery of: elevating systems, floor construction / platform construction, dosage system

with associated partners, packer with accompanying options (printing and

and label technology), output systems with metal and checkweigher detection systems.

Full supervision by VH Vertical Packaging

This means that you can be assured of an optimally efficient, future-proofed packaging line with a long service life. It goes without saying that support, maintenance and service are an integral part of our business.

Optimal support with MyCenturion

Packaging machine with a high uptime

Basic functionalities

We record all basic functions in a so-called machine master card. This basic data can be different for each machine. Recordings are subdivided into different main groups:

- Basic information such as heights, line integration, peripherals and standard options

- Software versions with accompanying custom-made updates

- Mechanical issues, both standard modifications and custom-made modifications

- Format and funnel information (including PDF film drawing)

- Recording the documentation of each master card. Such as layout, e-scheme, situational photos, CE declaration (generator)

Objectives of My Centurion

– Higher uptime of packaging machines

– Highest possible output of packaging machines

– Optimal operator convenience

– Effective guidance from VHVP

Extra functionalities

– Tracking mechanical improvements

– Tracking mechanical developments

– Tracking software improvements

– Tracking software developments

– Tracking purchase orders

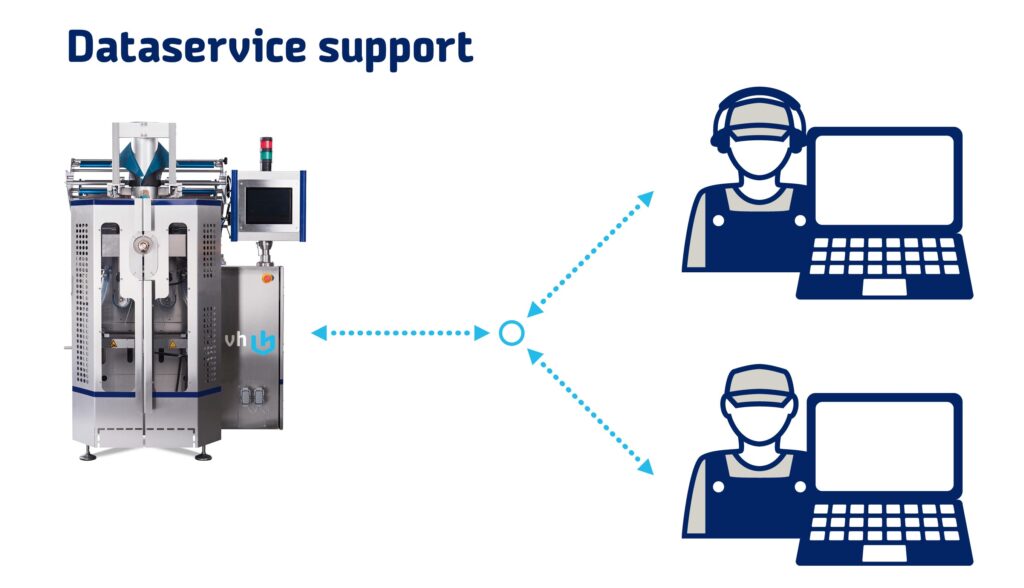

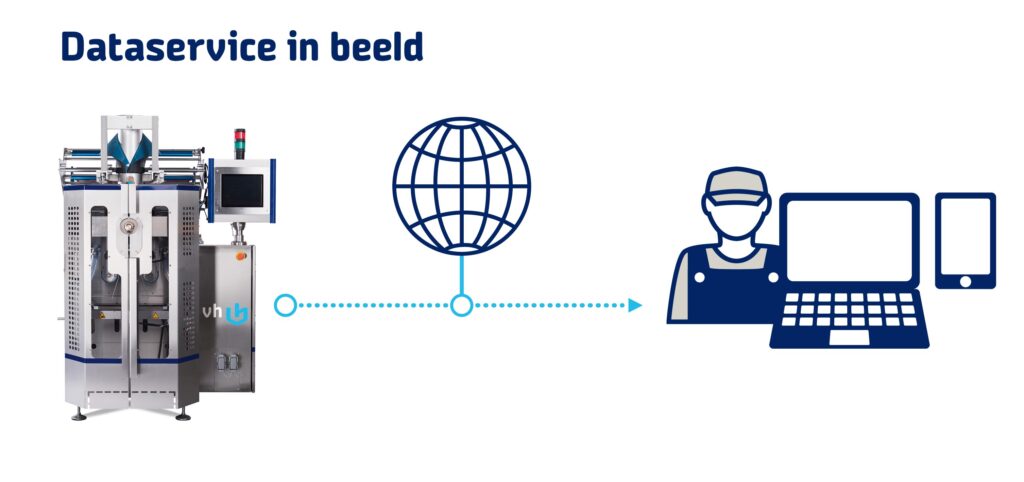

MyCenturion remote communication

OPC UA

MQTT

VNC Server

Mail Server

Tell me more about VH Powder

We are happy to give you more detailed information about this machine

For more information about your specific packaging requirements, please contact our specialists. Freek Jacobs and Marcel Wetemans are at your service. They will be happy to demonstrate the efficiency and high uptime of our Centurion machines. Call +31 (0) 495 550 733, send an email to sales@vhnl.com or use the response form.